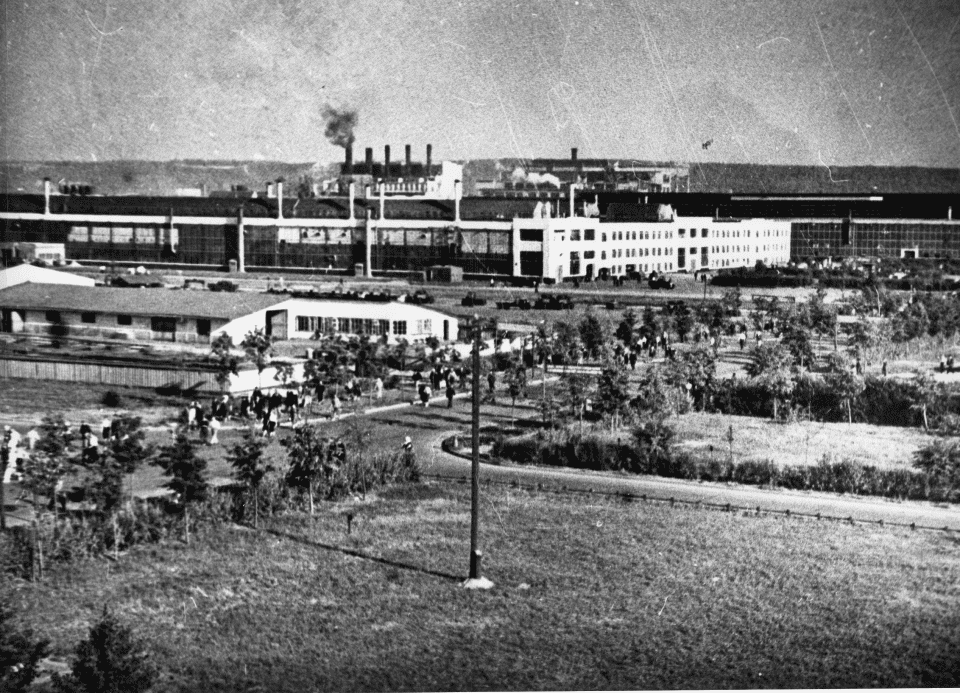

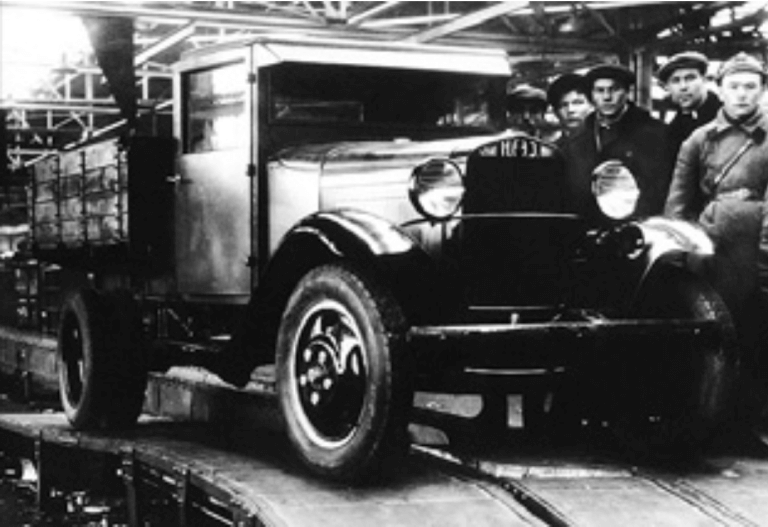

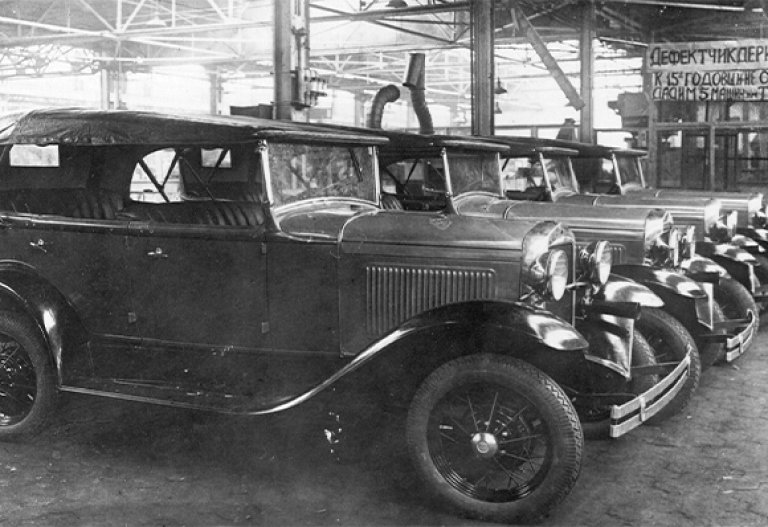

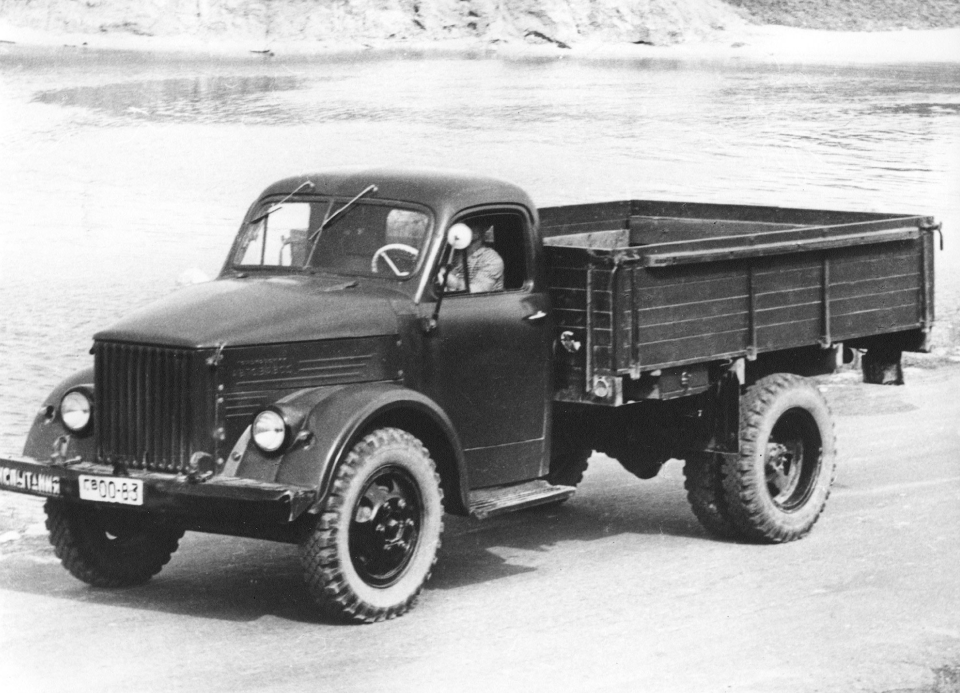

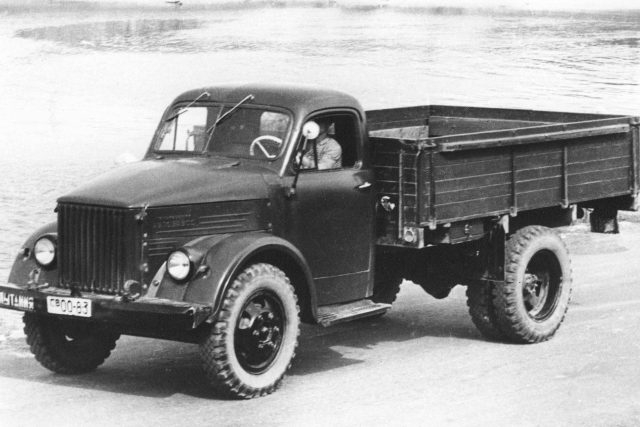

Resolution to start Stage 2 of the plant construction project was issued by the Soviet government.They built a wheel shop, a repair and maintenance shop, a forging shop, a tooling and mould shop, a valve and radiator shop, a body shop, two casting shops, an assembly shop, warehouses, an FMCG shop, a wood gas generator shop and other premises in mid- and late 1930s. Some of the older facilities, including a machining shop, a forging shop, a press shop, a lumber shop and a power plant, were rebuilt. Over 12,000 machines were installed.